The very high sustainability targets in the Wälderhaus could be achieved with the help of an insulating system made of Neopor®. The original product from BASF, the raw material maker, ensured that the insulation system could handle the specific challenges it faced for this application.

Sustainable construction — The Wälderhaus in Hamburg

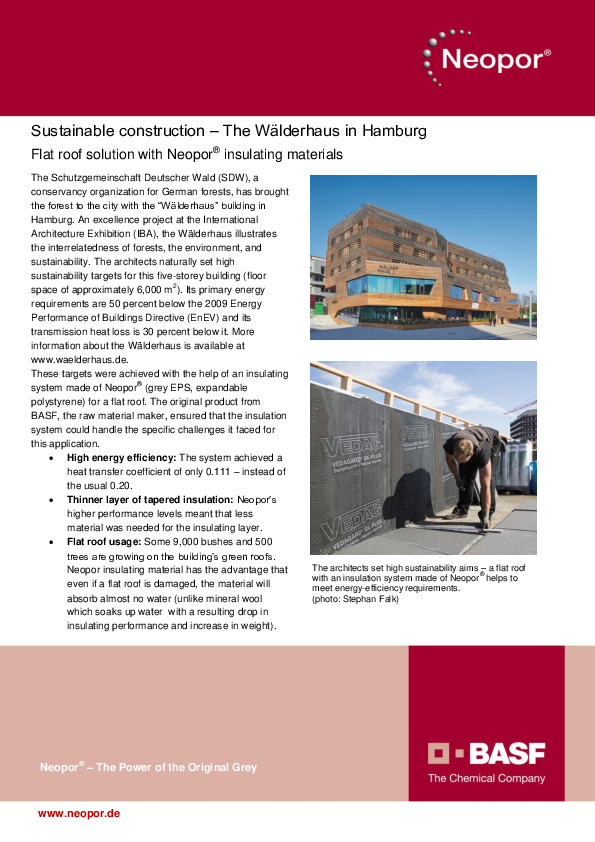

The Schutzgemeinschaft Deutscher Wald (SDW), a conservancy organization for German forests, has brought the forest to the city with the "Wälderhaus" building in Hamburg. An excellence project at the International Architecture Exhibition (IBA), the Wälderhaus illustrates the interrelatedness of forests, the environment, and sustainability. The architects naturally set high sustainability targets for this five-storey building (floor space of approximately 6,000 m2). Its primary energy requirements are 50 percent below the 2009 Energy Performance of Buildings Directive (EnEV) and its transmission heat loss is 30 percent below it. More information about the Wälderhaus is available at www.waelderhaus.de.

- High energy efficiency: The system achieved a heat transfer coefficient of only 0.111 — instead of the usual 0.20.

- Thinner layer of tapered insulation: Neopor's higher performance levels meant that less material was needed for the insulating layer.

- Flat roof usage: Some 9,000 bushes and 500 trees are growing on the building's green roofs. Neopor insulating material has the advantage that even if a flat roof is damaged, the material will absorb almost no water (unlike mineral wool which soaks up water with a resulting drop in insulating performance and increase in weight)

Additional advantages of Neopor:

- Rapid laying thanks to low weight.

- Low dust production during processing.

- Cost-efficient tapered roofing thanks to easy handling

- Safe processing with adherence to the quality guidelines of the Rigid Foam Industry Association (IVH) and the rules of the German Roofing Trade Association (ZVDH).

- Color suitable for construction sites, with little dirt accumulation and non-glare processing.

- Very economical with thermal insulation values comparable to high-priced alternative insulating systems.

- Non-decaying, dimensionally stable, water-repellent.

Tapered roof insulation

Tapered roof systems ensure that rainwater flows off flat roofs. A non-tapered roof, on which water can sit for a long period of time, is subject to considerable stress which in turn can critically reduce its working life. In order for water to run safely off, flat roofs should have a gradient of at least two percent. In addition to their efficient thermal insulating properties, wedge-shaped Neopor® insulating boards can be used to create gradients when constructing new buildings or modernizing existing non-tapered flat roofs. The tapered panels are calculated and cut (valleys and crests) at the factory by computer-aided systems.

Neopor is on the safe side even if roofs are damaged

An expert analysis of 20 damaged flat roofs that had been insulated with different materials showed that those insulated with EPS, despite water seepage, did not have to be completely redone. Flat roof insulating systems made of Neopor respond favorably to damage: they absorb only very small amounts of water and do not permanently lose their insulating properties.